News

Essential Products for Your Screen Printing Hustle

Screen printing has become a popular method for creating custom apparel, accessories, and promotional items. Whether you're a hobbyist or aspiring entrepreneur, having the right equipment and materials is crucial...

Essential Products for Your Screen Printing Hustle

Screen printing has become a popular method for creating custom apparel, accessories, and promotional items. Whether you're a hobbyist or aspiring entrepreneur, having the right equipment and materials is crucial...

Ink the Deal: The Ultimate Guide to Starting a ...

Introduction If you have a passion for art and a flair for entrepreneurship, starting a screen printing company could be the perfect venture for you. Screen printing is a versatile...

Ink the Deal: The Ultimate Guide to Starting a ...

Introduction If you have a passion for art and a flair for entrepreneurship, starting a screen printing company could be the perfect venture for you. Screen printing is a versatile...

Unveiling the Construction and Suppliers of Scr...

Screen printing has long been a popular method for creating vibrant and durable designs on various surfaces. One of the crucial components in the screen printing process is the screen...

Unveiling the Construction and Suppliers of Scr...

Screen printing has long been a popular method for creating vibrant and durable designs on various surfaces. One of the crucial components in the screen printing process is the screen...

What Screen Printing Chemicals Do You Need? An ...

Screen printing is a versatile and widely used technique for transferring designs onto various surfaces, including fabric, paper, glass, and plastic. Whether you're a professional screen printer or a hobbyist,...

What Screen Printing Chemicals Do You Need? An ...

Screen printing is a versatile and widely used technique for transferring designs onto various surfaces, including fabric, paper, glass, and plastic. Whether you're a professional screen printer or a hobbyist,...

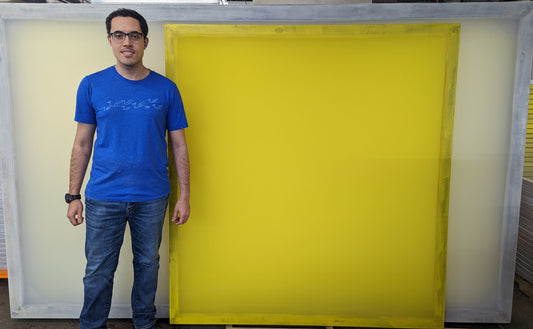

The Ultimate Guide to Large Format Screen Print...

Welcome to the ultimate guide on large format screen printing, where we will take you through everything you need to know about this fascinating technique. Whether you're a seasoned printing...

The Ultimate Guide to Large Format Screen Print...

Welcome to the ultimate guide on large format screen printing, where we will take you through everything you need to know about this fascinating technique. Whether you're a seasoned printing...

From Passion to Profit: A Step-by-Step Guide to...

How to Start a Screen Printing Business Are you passionate about art and design? Do you have a keen eye for detail and love working with your hands? Starting a...

From Passion to Profit: A Step-by-Step Guide to...

How to Start a Screen Printing Business Are you passionate about art and design? Do you have a keen eye for detail and love working with your hands? Starting a...