If you're a screen printer, you're probably already familiar with the importance of using the right mesh count. Choosing the correct mesh count is crucial for achieving the desired results in your prints. In this article, we'll take a closer look at what mesh count is, how to choose the right mesh count for your project, and the different applications of various mesh counts in screen printing.

Understanding Mesh Count in Screen Printing

Mesh count refers to the number of threads in a square inch of the screen mesh. A mesh with a higher thread count will have smaller holes, while a mesh with a lower thread count will have larger holes. The mesh count affects the amount of ink that can pass through the screen, as well as the level of detail that can be achieved in the print.Choosing the Right Mesh Count for your Screen Printing Projects

Choosing the right mesh count depends on a variety of factors, including the type of ink, the substrate, and the level of detail in the design. Generally speaking, the lower the mesh count, the more ink will be deposited on the substrate, resulting in a thicker print. Higher mesh counts are ideal for achieving more detailed designs and producing finer lines and halftones.Mesh Counts for Different Applications

Different mesh counts are suitable for different types of applications. Here's a breakdown of some common mesh counts and their applications:

60-86 Mesh Count

This mesh count is ideal for printing on heavier fabrics such as sweatshirts, tote bags, and canvas. The thicker ink deposit creates a more opaque print, and the larger holes allow for thicker inks to pass through the screen.110-156 Mesh Count

This mesh count is suitable for printing on medium-weight fabrics such as t-shirts and jersey knit. It's also ideal for printing on paper and other flat surfaces.200-230 Mesh Count

This mesh count is ideal for printing on lighter fabrics such as sheer and lightweight cotton. It's also great for printing fine details and halftones.305-355 Mesh Count

This mesh count is suitable for printing on very lightweight fabrics such as silk and nylon. It's also ideal for printing highly detailed designs and halftones.Tips for Using Different Mesh Counts for Screen Printing

Here are some tips for using different mesh counts in your screen printing projects:- When printing on dark fabrics, use a lower mesh count to achieve a thicker print.

- When printing on light fabrics, use a higher mesh count to achieve a finer print.

- Use a higher mesh count when printing fine details and halftones.

- Use a lower mesh count when printing bold designs and solid areas.

- Experiment with different mesh counts to find the right one for your project.

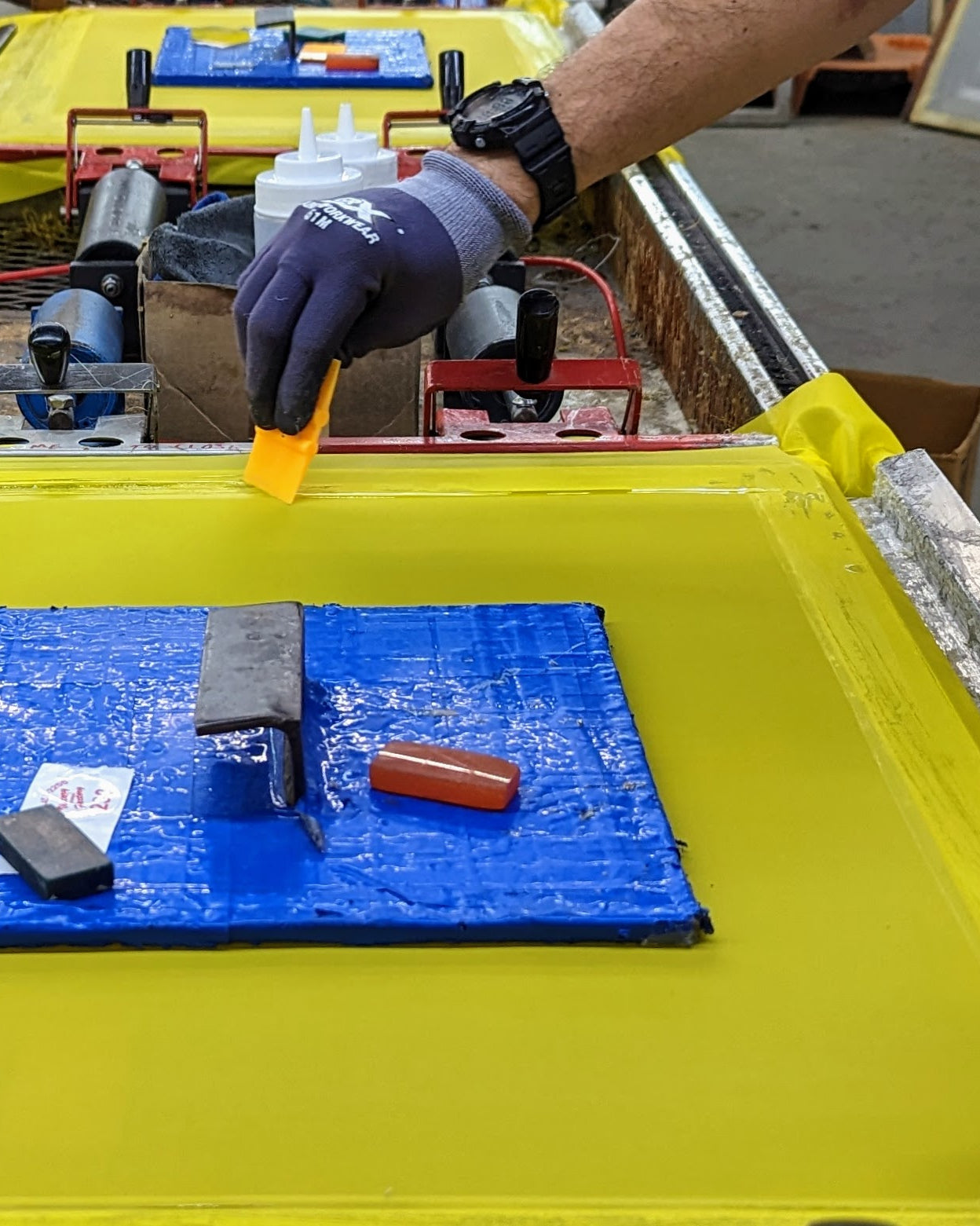

- Use Mesh Counter to determine what mesh is on your screen.

Conclusion

Choosing the right mesh count is essential for achieving the desired results in your screen printing projects. By understanding the different mesh counts and their applications, you can select the ideal mesh count for your specific project. Remember to experiment with different mesh counts to find the perfect one for your needs. Victory Screen Factory has large selection of frames with all mesh countsFAQs

- What is mesh count in screen printing? Mesh count refers to the number of threads in a square inch of the screen mesh.

- What mesh count should I use for printing on t-shirts? A mesh count of 110-156 is suitable for printing on t-shirts.

- Can I use the same mesh count for different types of inks? No, different inks require different mesh counts for optimal results.

- What is the highest mesh count? The highest mesh count is typically around 400.

- How do I determine the ideal mesh count for my project? Consider the type of ink, the substrate, and the level of detail in the design to determine the ideal mesh count for your project.