Unlocking the Secrets of Screen Printing Success: Best Practices for Aluminum Frames

Share

Introduction

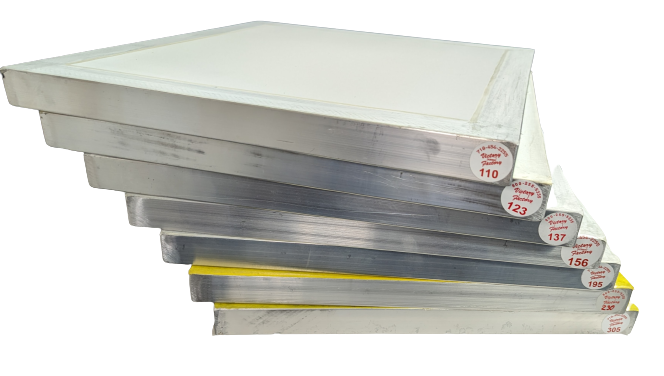

Screen printing has long been a versatile and popular method for transferring intricate designs onto various surfaces, from textiles and apparel to promotional materials and signage. One of the critical components of successful screen printing is the choice of frames, and aluminum frames have emerged as a top choice among professionals in the industry. In this comprehensive guide, we will delve into the world of screen printing aluminum frames and uncover the best practices for achieving outstanding results in your screen printing projects.

I. The Advantages of Screen Printing Aluminum Frames

Before we dive into the best practices, let's first understand why screen printing with aluminum frames is a smart choice. Aluminum frames offer several key advantages that make them stand out among other frame materials:

- Durability: Aluminum frames are incredibly durable and resistant to corrosion, making them suitable for long-term use. Unlike wood frames that can warp or lose their shape over time, aluminum frames maintain their structural integrity.

- Lightweight: Aluminum frames are lightweight, making them easy to handle and transport. This feature is especially advantageous for screen printers who need to move their frames frequently.

- Stability: Aluminum frames provide excellent stability, ensuring that your screens remain taut and consistent during the printing process. This stability leads to more precise and consistent results.

- Reusability: Aluminum frames can be reused multiple times with proper care and maintenance. This reusability not only saves money but also reduces environmental impact.

- Compatibility: Aluminum frames are compatible with various mesh counts, allowing screen printers to choose the right mesh for their specific project requirements.

II. Choosing the Right Aluminum Frame

Now that we understand the benefits of aluminum frames, it's essential to select the right frame for your screen printing needs. Consider the following factors:

- Frame Size: Choose a frame size that accommodates the size of your design and substrate. A frame that is too small can lead to insufficient coverage, while a frame that is too large may be challenging to manage.

- Mesh Count: Select the appropriate mesh count based on the level of detail in your design. Higher mesh counts are suitable for fine detail work, while lower mesh counts are better for bold and solid designs.

- Frame Thickness: Aluminum frames come in various thicknesses. Thicker frames offer increased durability and stability, but thinner frames can be more cost-effective and easier to handle.

- Frame Tension: Ensure that your aluminum frame has proper tension to keep the screen mesh tight and even. You can use a tension meter to measure and adjust the tension as needed.

III. Preparing the Screen

Properly preparing and stretching the screen mesh on your aluminum frame is a crucial step in achieving high-quality screen prints. Follow these steps:

- Degreasing: Clean the aluminum frame thoroughly to remove any dirt, grease, or residue. This ensures proper adhesion of the emulsion and prevents contamination. Use a Victory Factory Degreaser for optimal cleaning.

- Applying Emulsion: Coat the screen mesh with emulsion using a scoop coater. Make sure to apply an even and consistent layer. Allow the emulsion to dry in a dark, dust-free environment. We recommend Ulano or Saati emulsions.

- Exposing the Design: Place your design or artwork onto the coated screen and expose it to UV light. The emulsion will harden where the design is exposed, creating the stencil for printing.

- Washing Out the Stencil: After exposure, rinse the screen with a gentle stream of water to wash away the unexposed emulsion, leaving behind the stencil. Allow the screen to dry thoroughly.

IV. Best Printing Practices with Aluminum Frames

With your aluminum frame and stretched screen ready, it's time to dive into the best practices for screen printing success:

- Ink Selection: Choose the right ink for your project, considering factors like substrate type, color opacity, and curing requirements. Conduct ink compatibility tests if necessary. https://screenprinting.pro/is-it-better-to-start-screen-printing-with-water-based-or-plastisol-inks/

- Proper Setup: Ensure your printing press is set up correctly, with the screen securely attached and positioned accurately over the substrate. Adjust the off-contact distance and squeegee angle for optimal results.

- Consistent Pressure: Maintain consistent and even pressure during the printing process. Inconsistent pressure can lead to uneven ink deposits and poor print quality.

- Test Prints: Always perform test prints to fine-tune your setup, such as adjusting ink flow, squeegee pressure, and screen alignment. This helps identify and address any issues before the final print run.

- Curing: Follow the recommended curing instructions for your chosen ink. Proper curing ensures that the ink bonds securely to the substrate, preventing premature wear and fading.

Conclusion

Screen printing with aluminum frames offers a world of possibilities for creating stunning, high-quality prints. By following the best practices outlined in this guide, you can unlock the full potential of screen printing aluminum frames and achieve exceptional results in your projects.

FAQ

FAQ 1: What is the recommended mesh count for aluminum frames?

Answer: The ideal mesh count depends on your specific printing project. Higher mesh counts, such as 230-305, are suitable for fine detail work and halftone printing, while lower mesh counts, like 110-160, are better for bold and solid designs. Choose a mesh count that matches the level of detail you want to achieve in your prints.

FAQ 2: How can I clean and maintain aluminum frames for reuse?

Answer: To clean and maintain aluminum frames for reuse, start by removing any excess ink immediately after printing. Then, wash the screens with a gentle, water-based screen cleaning solution to remove emulsion residue and ink stains. After cleaning, ensure the frames are thoroughly dried before storing them in a cool, dry place. Regular maintenance and proper storage will extend the life of your aluminum frames.

FAQ 3: Can aluminum frames be used for printing on different substrates?

Answer: Yes, aluminum frames are versatile and can be used for printing on a wide range of substrates, including textiles, paper, cardboard, plastics, and more. However, it's essential to choose the right mesh count and ink type that are compatible with the specific substrate you intend to print on for the best results.

FAQ 4: What is the recommended tension level for screen printing aluminum frames?

Answer: The recommended tension level for aluminum frames typically falls within the range of 20-30 Newtons per centimeter (N/cm) or 15-25 pounds per square inch (psi). It's essential to maintain consistent tension across the entire screen to ensure even ink deposition and crisp prints. Use a tension meter to measure and adjust the tension as needed.

FAQ 5: Can I reclaim and reuse aluminum frames with a new design?

Answer: Yes, aluminum frames can be reclaimed and reused with a new design. To do this, you'll need to remove the existing emulsion by using a stencil remover or emulsion remover. Once the frame is clean, you can apply a new emulsion coating, expose it with your new design, and proceed with printing as usual. Properly reclaiming and reusing frames can save both time and resources in your screen printing workflow.

We hope you found this guide valuable in your screen printing endeavors. If you have any questions, tips to share, or experiences to discuss regarding screen printing aluminum frames, please feel free to leave a comment below. Your feedback and insights are always welcome and appreciated. Happy printing!