Ulano EZ Film 30

Couldn't load pickup availability

High-Quality Stencils in a Flash

Unlock Efficiency and Quality with EZ FILM 30

Looking for a game-changer in your textile printing process? Look no further than EZ FILM 30, the ultimate solution for high-quality stencils with lightning-fast results. Designed as a viable alternative to direct emulsion, this 30-micron textile capillary direct film is engineered to optimize your printing workflow. Discover the exceptional benefits that make EZ FILM 30 the top choice for savvy printers.

- Fast Drying, Fast Exposing: EZ FILM 30 is specially formulated to dry rapidly, saving you valuable time during the production process. Say goodbye to long waiting times and hello to efficiency.

- Pure Photopolymer Perfection: Crafted with pure photopolymer (SBQ), EZ FILM 30 ensures outstanding stencil quality, consistently delivering sharp and precise prints. Elevate your designs with confidence.

- Economical Alternative: With EZ FILM 30, you don't have to compromise on quality to save costs. Priced competitively, this capillary film provides a cost-effective solution without sacrificing performance.

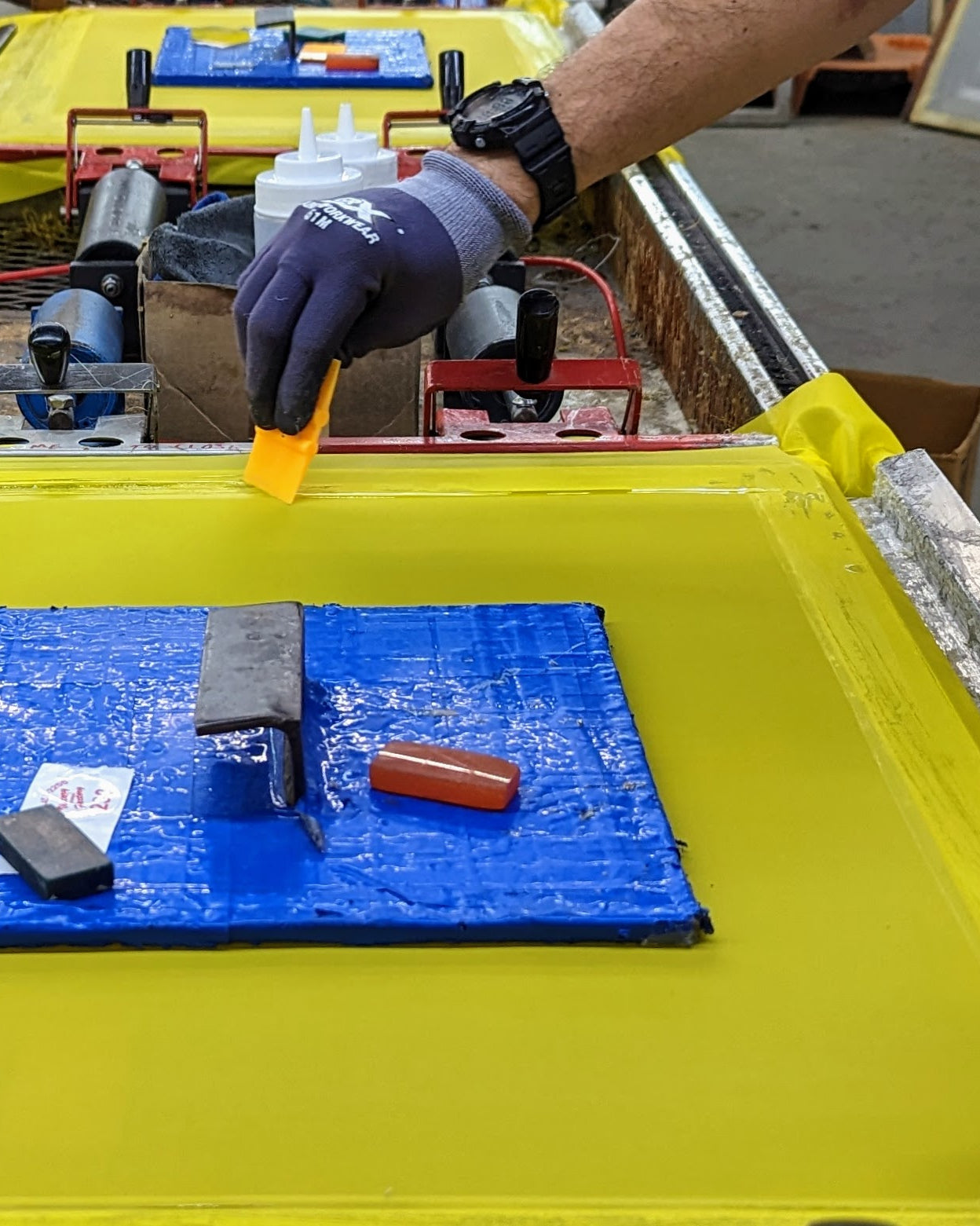

- Mess-Free Application: Bid farewell to the mess and waste associated with traditional emulsion methods. EZ FILM 30 offers a clean and hassle-free application, allowing you to focus on what you do best—creating remarkable prints.

- Consistent Results: Achieve consistent results time after time. EZ FILM 30 maintains a controlled-coating thickness, ensuring consistent exposure time and ink deposit for predictable and reliable outcomes.

Ideal for Versatile Textile Printing

Your Perfect Match: EZ FILM 30 for All Mesh Counts

Experience versatility like never before with EZ FILM 30, the go-to solution for a wide range of mesh counts. Whether you're working with 230 threads per inch or 419 threads per inch, this remarkable capillary direct film delivers outstanding results. Discover why EZ FILM 30 is the ideal choice for your textile printing needs.

- Perfect Mesh Compatibility: EZ FILM 30 is engineered to excel with mesh counts ranging from 230 to 419 threads per inch (90 and 165/cm). No matter the intricacy of your design, this capillary film provides consistent and reliable performance.

- Pink Precision: Stand out from the crowd with EZ FILM 30's eye-catching pink color. Not only does it add a touch of vibrancy to your printing process, but it also allows for easy visibility and alignment during setup.

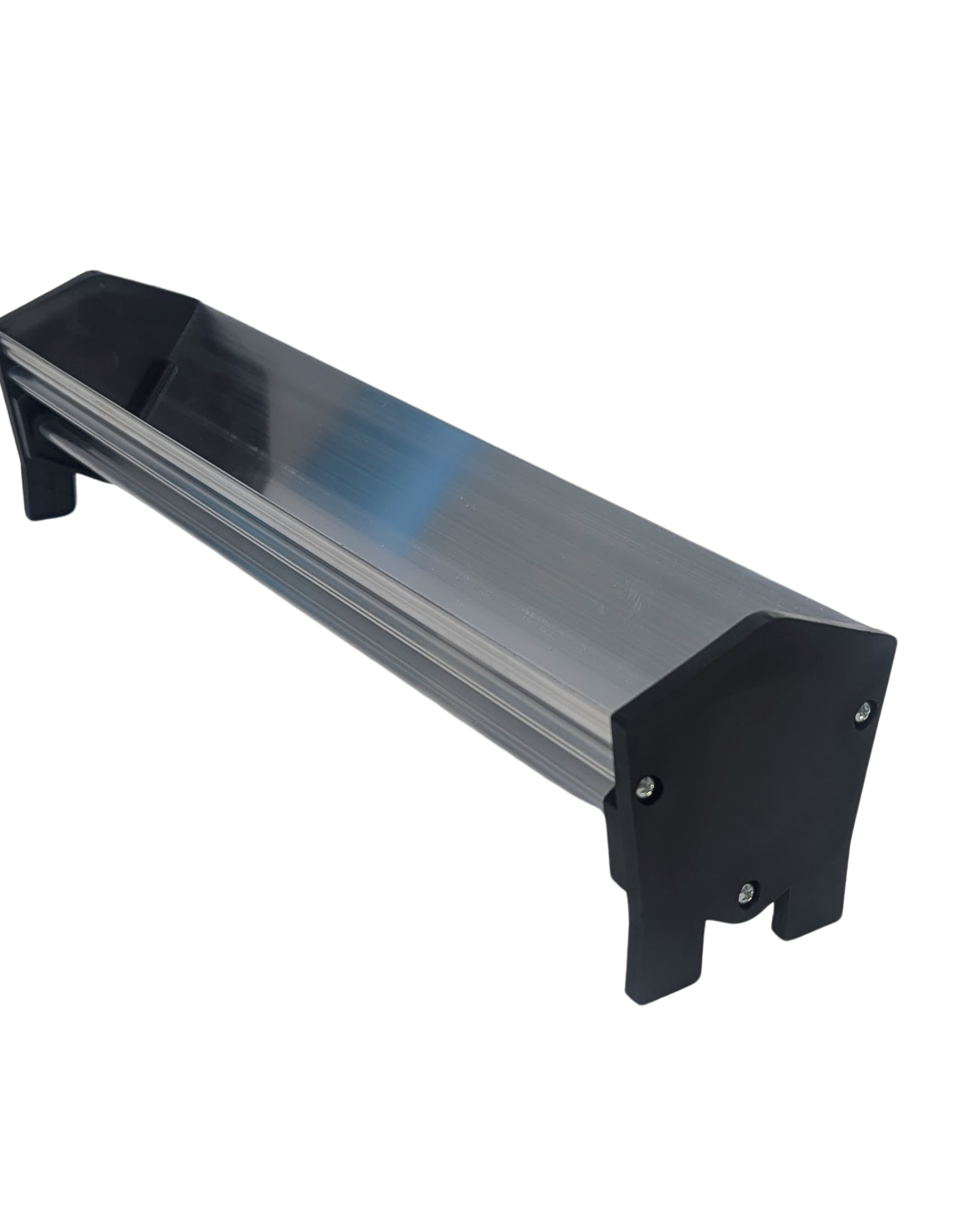

- Matte-Surface Polyester: The 300-gauge matte-surface polyester coating of EZ FILM 30 ensures excellent adhesion and provides a smooth and reliable surface for your stencil creation. Experience superior print quality and durability.

- Compatible with QTX® Direct Emulsion: Want to enhance the adhesion of EZ FILM 30? You can choose to adhere it with plain water or opt for the added benefits of QTX® direct emulsion. The choice is yours, providing flexibility and convenience.

Unleash Efficiency with Prepackaged Convenience

Simplify Your Workflow with EZ FILM 30

When time is of the essence, convenience becomes paramount. EZ FILM 30 is here to streamline your workflow and simplify your printing process. Discover how this revolutionary capillary direct film saves you valuable time and effort, ensuring a hassle-free experience from start to finish.

- Ready-to-Use Prepackaged Sheets: EZ FILM 30 comes in convenient prepackaged sheets, eliminating the need for time-consuming manual cutting or measuring. Simply grab a sheet and get started on your next print job effortlessly.

- Quick and Effortless Adhesion: Say goodbye to complicated and messy setup. EZ FILM 30 adheres perfectly, ensuring a seamless application. Whether you choose plain water or QTX® direct emulsion, the process is quick and hassle-free.

- Rapid Exposing: Time is money in the printing industry, and EZ FILM 30 understands that. This capillary film exposes rapidly, allowing you to speed up your production process without compromising quality.

- Minimal Cleanup and Waste: Unlike traditional emulsion methods, EZ FILM 30 leaves no mess behind. Enjoy a cleaner workspace and reduce waste, allowing you to focus on what matters most—creating exceptional prints.

BASE EXPOSURE TABLE for EZ FILM 30 at 40 inches (100 cm.) on white polyester or nylon:

LIGHT SOURCE | EZ FILM 30 EXPOSURE TIME

Carbon Arc

30 amps | 78 sec.

110 amps | 21 sec.

Metal Halide

1000 watts | 52 sec.

2000 watts | 27 sec.

3000 watts | 17 sec.

4000 watts | 13 sec.

5000 watts | 11 sec.

7000 watts | 9 sec.

Pulsed Xenon

2000 watts | 152 sec.

5000 watts | 61 sec.

8000 watts | 38 sec.

Mercury Vapor

1000 watts | 70 sec.

2000 watts | 33 sec.

4000 watts |17 sec.

Fluorescent Tubes*

40 watts | 152 sec.

EXPOSURE VARIABLES FACTORS

MESH

Dyed Mesh 1.5-2.0

IMAGING

Fine line reverse printing 1.2

ADHERING

Direct/Indirect Method using QTX® 1.5

TAPED-UP POSITIVES

Taped-up or montage positives, per layer 1.1

EXPOSURE DISTANCE

20”/50 cm 0.25

24”/60 cm 0.36

28”/70 cm 0.49

32”/80 cm 0.64

36”/90 cm 0.81

40”/100 cm 1.00

44”/110 cm 1.21

48”/120 cm 1.44

52”/130 cm 1.69

56”/140 cm 1.95

60”/150 cm 2.25

72”/180 cm 3.24

84”/210 cm 4.41

100”/250 cm 6.25