Ulano Screen Filler #65

$38.00

Unit price

/

Unavailable

Couldn't load pickup availability

Superior Blockout Solution for Pristine Results

Achieve Impeccable Screen Printing with Ulano Screen Filler #65

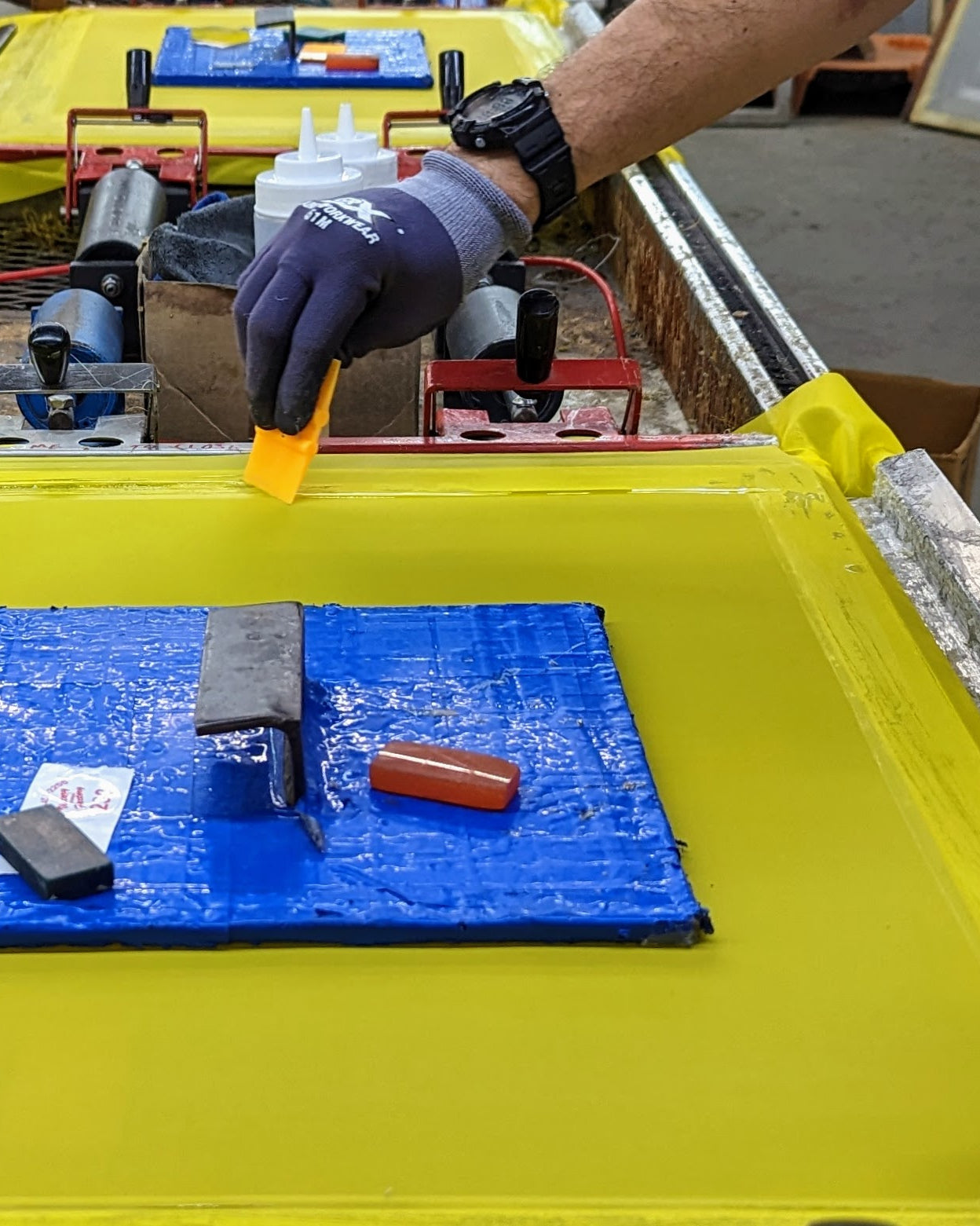

Introducing Ulano Screen Filler #65, the ultimate solution for flawless screen printing results. Whether you're a seasoned professional or just starting your journey in the world of screen printing, this high-quality blue solvent-resistant blockout is designed to elevate your craft to new heights. With its exceptional properties and versatility, Ulano Screen Filler #65 is the go-to choice for artists and enthusiasts alike.

Unleash your creativity with confidence as Ulano Screen Filler #65 provides the perfect barrier to prevent ink from penetrating unwanted areas on your screen. Its vibrant blue color ensures clear visibility, allowing you to make precise touch-ups or blockouts effortlessly. With fine to medium mesh counts, this non-flammable and water-soluble formula offers the flexibility you need for various printing projects.

Versatile and User-Friendly

Unleash Your Creativity with Ease

Ulano Screen Filler #65 is a user-friendly screen printing companion that adapts to your needs. Whether you prefer working at full strength or desire a more diluted consistency, this incredible filler can be easily customized. Simply add water to achieve your desired level of thinness, enabling you to have full control over your printing process.

One of the remarkable features of Ulano Screen Filler #65 is its compatibility with all stencil systems and mesh types. No matter what your setup is, this filler will seamlessly integrate into your workflow, making it a versatile and reliable choice. You can confidently use it with non-aqueous inks, ensuring vibrant and long-lasting prints that captivate your audience.

Safety and Environmental Consciousness

Embrace a Safe and Sustainable Printing Journey

At Victory Screen Factory, we prioritize your safety and the environment. Ulano Screen Filler #65 is biodegradable and free from organic solvents. This makes it suitable for use even in unventilated rooms. Say goodbye to the concerns of harmful fumes and embrace a comfortable and worry-free printing experience.

Not only is Ulano Screen Filler #65 safe for you, but it also aligns with our commitment to sustainability. Its water-soluble nature allows for easy reclamation and cleanup, reducing waste and minimizing your ecological footprint. You can feel confident knowing that your artistic endeavors are contributing to a greener future.

INSTRUCTIONS

- Before printing, completely air dry screen filler the same way you would dry your stencil.

- Use Extra Heavy Blockout No. 10 for easier handling, for coverage with a single coating or with coarse mesh.

- For direct emulsion and CDF Direct-Film stencils: Pour a small amount onto the border area of the fully processed and dried stencil on the printing side of the screen. Scrape it evenly into the mesh, using a piece of cardboard or plastic. Apply a second, "reinforcing" coat to the squeegee side of the screen, if necessary.

- For Indirect System stencils: For best register and a strong "knit" between stencil and screen filler, apply the screen filler, as above, when the screen mesh is dry, but before the indirect film is completely dry. Apply the screen filler to the printing side of the screen, going over the edges of the backing sheet.

- For touchups: Use full strength or thin with tap water and touch up as needed with either end of an artist's brush.

- To remove: After ink removal, but before stencil removal, dissolve with water.

- Air dries, so keep the cap on.

Recommended for use on all mesh, with all stencil systems. Use only with non-aqueous inks.

Ulano Screen Filler #65