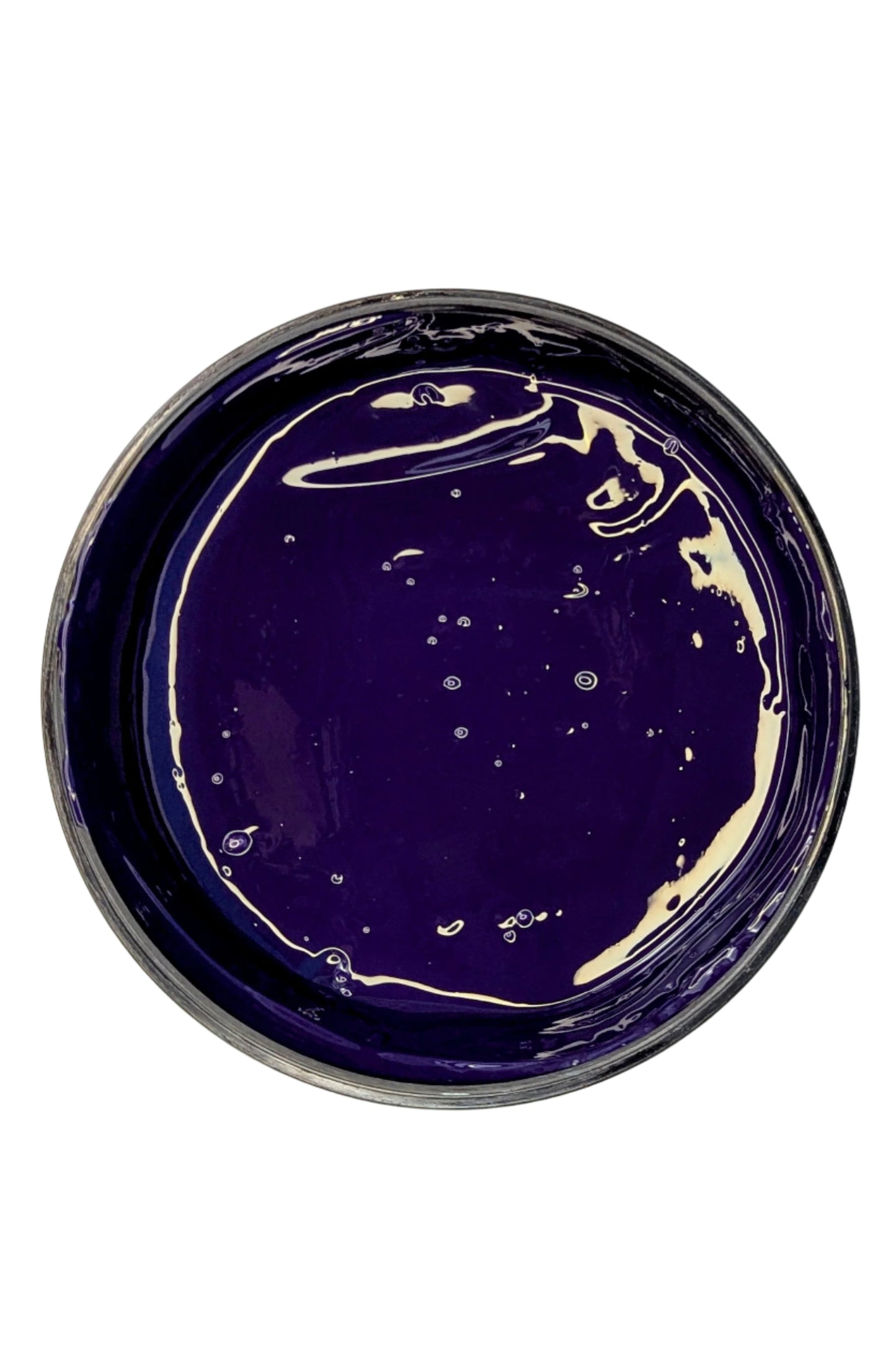

Purple Victory Bio Ink Water Base

Purple Victory Bio Ink Water Base

Purple Victory Bio Ink - Water-Based Garment Printing Ink

The Perfect Solution for Eco-Conscious Printing

Victory Bio Ink is an exceptional alternative to traditional PVC-based plastisol inks, offering a safer, more sustainable solution without sacrificing performance. It’s specifically designed for printers who need versatility, durability, and vibrant prints on a wide range of substrates.

Key Benefits:

✅ Eco-Friendly Alternative:

A remarkable choice for those seeking a non-toxic substitute to PVC plastisol inks, helping you meet environmental and safety standards.

✅ Versatile Substrate Compatibility:

Ideal for printing on:

- 100% Cotton

- Cotton/Polyester Blends (50/50)

- 100% Polyester

- Highly Elastic Fabrics like Lycra

✅ Superior Screen Stability:

Formulated for very slow drying at room temperature, ensuring your screen remains unclogged during long production runs.

✅ Exceptional Stretch & Elongation:

Achieves elongation over 1000%, surpassing competitors like Dow Corning (750-850%) and BLUESIL (215-370%). Perfect for high-stretch garments without cracking.

✅ Enhanced Fiber Control:

Effectively blocks fiber fibrillation, particularly on untreated cotton, ensuring smoother, cleaner prints.

✅ Vivid Coverage on Dark Fabrics:

Offers uniform, high-opacity coverage on dark substrates without the need for a white underbase.

✅ Durability You Can Trust:

Strong adhesion across all substrates with excellent wash fastness and high crack resistance.

✅ CPSIA Compliant:

- Lead Content: <300 ppm (Section 101)

- Phthalates: <0.1% for DBP, DEHP, DINP, DIDP, DnOP, DOP (Section 108)

Application Guidelines:

Recommended Fabrics:

- Cotton, Cotton/Polyester Blends, Polyester

- Synthetic Fabrics (e.g., Lycra and other highly elastic materials)

Finish:

Durable, soft-hand finish that your customers will love.

Mesh Recommendations:

Use mesh counts between 86 to 230T monofilament polyester (34-90T European mesh).

Optimal mesh count should be determined by the end user based on specific print requirements.

Stencil:

Use a water-resistant dual-sensitized direct emulsion or SBQ pre-sensitized photo emulsion.

Fusion/Drying Conditions:

- Automatic Press: Cure at approximately 300°F (150°C) for 1-2 minutes.

-

Cotton Substrates: May require a slightly longer curing time.

Perform ladder curing tests to optimize curing parameters for your setup.

Modifications & Additives:

- BIO-RE 705 (Rheology Modifier & Retarder): Add 1-2% by weight for improved ink flow and extended open time.

- Other Humectants: Compatible with conventional humectants for enhanced performance.

Storage & Safety:

- Store between 41°F (5°C) and 120°F (49°C).

- Unopened containers are protected against microbial contamination.

- Opened containers should be handled with care to avoid microbial attack—maintain proper hygiene.

Ink Cleaner:

- Use BIO-IC 510 for an instant, biodegradable cleaning solution that’s non-petrochemical-based.

🚫 Caution: Wet ink can create slippery surfaces—exercise care in your work environment.

Color Range:

Victory Bio Inks are available in a wide spectrum of vibrant, non-leaded colors to meet any design need:

- Whites: HO White

- Yellows: Lemon Yellow, Chrome Yellow, Athletic Gold, Vegas Gold

- Greens: Bright Green, Kelly Green, Forest Green, Hunter Green

- Blues: Reflex Blue, Royal Blue, Navy Blue, Light Blue

- Purples: Light Purple, Deep Purple

- Reds: Cardinal Red, Scarlet Red, Deep Red, Maroon

- Neutrals: Heather Grey, Russell Grey, Black

(See full color list for detailed options.)

Why Choose Victory Bio Ink?

Whether you're printing for athletic wear, promotional garments, or fashion, Victory Bio Ink provides unparalleled stretch, durability, and eco-conscious printing solutions. Its versatility across various fabrics and exceptional print quality make it the ultimate choice for professional printers seeking sustainable alternatives.

👉 Experience the Victory difference—print brighter, stretch further, and stay eco-friendly!

Product features

Product features

Materials and care

Materials and care

Merchandising tips

Merchandising tips

Share